We solve your building problems

Solution

SHOBI construction method for waterproofing, rustproofing, and stainproofing

Waterproofing,rust-proofing,and painting all at once!

SHOBI method is friendly to both people and the environment and offers excellent water resistance, permeability, rust resistance, and antifouling properties. It also uses flame retardants and fire-resistant paints to quickly and reliably resolve your concerns.

SB-100

SB-100 is used for waterproofing effect of the surface of wet concrete, blocks, brick surface, fiber cement boards, plywood, wood, etc.

Unlike conventional sealers, It not only hardens the surface of the adherend, but also penetrates deeply and adheres to the adherend to strengthen adhesion with the top coat.

It is also well bonded to the wet surface and oil surface, and can be used as a primer for the wet surface and oil surface.

For materials that are permeable, dilution with 0.25 to 2x water allows for better penetration and adherence.

SB-110

SB-110 is a type with higher viscosity and solidification than SB-100.

Since the SB-100 is too permeable, this was set considering injecting it into a moderately crack that cannot be handled.

Also, because of the rapid drying, it is effective as an anti-rust primer on the rust surface.

Similar to SB-100, it adheres well to the wet surface and oil surface, and can be used as a primer for wet surface and oil surface.

SB-500

SB-500 is suitable for the expansion of parts where many stresses are applied and parts with different inflation rates due to the adhesive in the elastic regeneration section.

Combining with SB-100 also supports wet surfaces.

SB-13

SB-13 has excellent adhesion strength for silica sand mortar and polymer mortar to aging concrete.

When used as a resin mortar by mixing SB-13 and fresh water at a ratio of 1:1, it is expected to have sufficient adhesion strength (even if the lift runs, it will not break)

The peel strength does not decrease even in wet conditions.

The adhesion strength of silica sand mortar is 25% higher than normal (*according to the manufacturer).

※Anionic resin mortar is not available elsewhere

New product SB-9

SHOBI Method TechnologiesTechnology

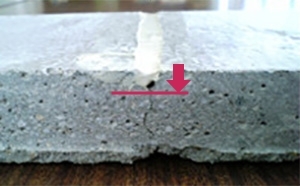

Technology 1

Osmotic adhesion

water/weak solvent epoxy resin paint

SB-100 SB-110 SB-500

-

Previous repair materials

SB-100 SB-110 SB-500 can fill the cracks in the concrete with putty on the surface

-

SB Method Repair Material

Our own improved water-based epoxy penetrates deep into the cracks and adheres

Strength to attach the entire crack

It can be applied on wet or oily surfaces

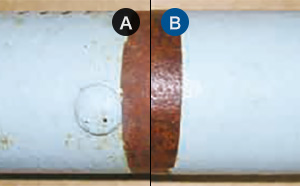

Technology2

anti-rust

water/weak solvent epoxy resin paint

SB-100 SB-110 SB-500

-

-

- A

- Antirust and paint-based parts of other companies have been rusted in the second half of the repair period.

- B

- The part painted on the rust stop of the SB construction method has no rust floating and has long-term rust control.

No rust floating in SB method for a long time

Painting OK even in wet condition

Rust are can be painted after three kinds of kelen

Precautions

- ・When the surface temperature is 5℃ or less and the humidity is 85% or higher, avoid the construction as much as possible.

- ・When it is likely to rain, do not perform construction.

- ・Never use the pot life after agitation.

- ・Wash the equipment used immediately after construction with hot water, water, or neutral detergent.

- ・Be careful not to touch the skin or eyes directly or to inhale steam or mist.

- ・Prolonged contact may cause skin hypersensitivity and itching of the eyes.

- In case of attaching, wash with water and rinse with water for at least 15 minutes and consult a doctor.